Metal roofing performs well in PNW rain and wind when installed as a system. Here’s why details, flashing, and ventilation matter more than panels.

Quick navigation

- Intro

- Metal sheds water fast

- A system, not just panels

- What fails first in PNW roofs

- Wind performance and edge details

- Wind-driven rain and transitions

- Condensation and ventilation

- Durability and maintenance

- Installation quality over panel brand

- How to compare bids and scope

- When metal makes sense

- Frequently Asked Questions

- What to do next

Why Metal Roofing Performs So Well in Rainy + Windy Pacific Northwest Climates

In Western Washington, roofs face conditions most of the country doesn’t deal with. Persistent rain, wind-driven moisture from multiple directions, moss growth, and rapid temperature swings between wet and dry cycles.

If you live near the Puget Sound or on an island like Oak Harbor, add salt air and steady wind exposure to that list.

Metal roofing performs well here, but not just because the panels themselves are durable. It works because a properly installed metal roof is a complete system designed to manage water, resist wind uplift, control ventilation, and handle movement.

Panels are one piece. The rest of the system is what keeps your home dry.

This isn’t about marketing claims. It’s about how the roof is built.

Metal Works Here Because It Sheds Water Fast

Metal roofing sheds water faster than asphalt shingles. Water doesn’t sit on the surface long enough to find small gaps or worn spots. It runs off.

Asphalt shingles rely on overlapping layers and aging adhesive seals between tabs. Those seals work well when new, but granule loss and UV exposure weaken them over time.

Wind-driven rain can work under tabs once seals start to fail. In the Seattle area, where rain can come horizontally during storm systems, that matters.

Metal panels use interlocking seams or standing seam profiles that shed water by design. There’s less reliance on adhesive bonds that degrade.

Metal Roofing Is a System, Not Just Panels

When contractors talk about metal roofing, they should be describing a system, not just panel color and gauge.

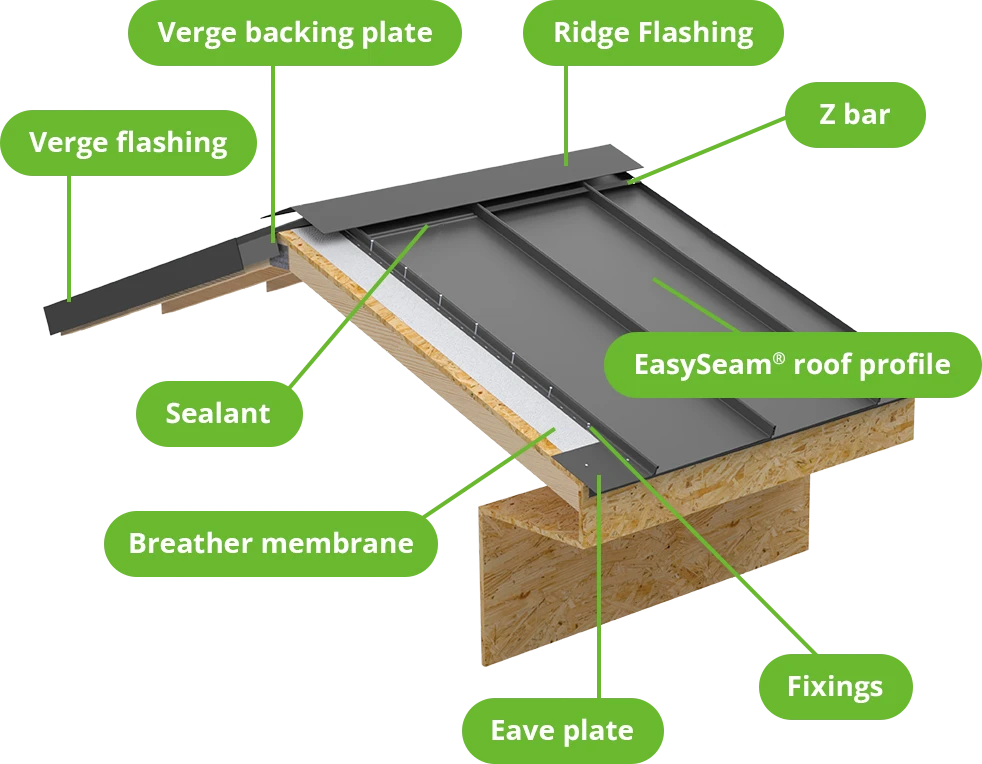

A complete metal roof system includes:

- Panels (standing seam or exposed-fastener profiles)

- Underlayment (synthetic, high-temp rated for metal)

- Flashings (step flashing, valley metal, wall transitions, chimney cricket)

- Clips and fasteners (allow thermal movement, resist uplift)

- Ventilation (ridge vent, soffit intake, balanced airflow)

- Edge details (drip edge, rake trim, eave starter, gable trim)

Each component has a job. Panels keep bulk water out. Underlayment is the secondary water barrier at transitions.

Flashings direct water away from intersections. Clips allow the metal to expand and contract without buckling. Ventilation prevents condensation buildup under the deck.

If any part of the system is missing or done incorrectly, the roof underperforms regardless of panel quality.

If you want a deeper breakdown of standing seam systems, see Standing Seam Metal Roofing in the PNW.

What Fails First in Pacific Northwest Roofs

Most roof leaks don’t start with the field of the roof. They start at transitions, edges, and penetrations.

Understanding what fails helps you evaluate whether a roofing proposal addresses the actual vulnerabilities.

For more context on common failure patterns, see Why Roofs Fail in the Pacific Northwest.

Valleys take the most water volume and are prone to debris buildup and ice damming at higher elevations. Improperly installed valley metal or missing underlayment causes leaks.

Wall transitions and step flashing fail when flashing isn’t woven correctly with siding or when caulk is used as a primary seal instead of metal.

Penetrations like pipe boots, vents, and exhaust fans crack, shrink, or lose their seal over time. Metal roofs use different boot types than asphalt, and incorrect choices fail early.

Chimneys and skylights require crickets (diverters) and proper counter-flashing. Shortcuts here let water sit and work its way under the roof.

Edges, eaves, and drip edge are where wind uplift starts. Missing or incorrect edge metal allows water to wick back under the roof deck.

Ridge and hips need ventilation and weather-tight caps. Gaps or improper fastening let wind-driven rain enter.

Ventilation imbalance (too much exhaust, not enough intake, or vice versa) creates negative pressure that pulls moisture into the attic or causes condensation under the deck.

Underlayment at transitions often gets skipped or done with the wrong product. Synthetic underlayment rated for metal’s heat is necessary. Felt paper degrades.

Metal roofing doesn’t eliminate these vulnerabilities. It just performs better when the system around it is done right.

Wind Performance: Why Edges and Details Matter

Wind uplift force hits roof edges first. Eaves, rakes, and ridges see the highest uplift pressure during storms.

On coastal or island sites near Oak Harbor, steady wind makes this a constant factor, not just a storm event.

Standing seam metal roofs use concealed clips that attach to the deck and allow the panel to float. The clip resists uplift, but the panel can still move slightly with thermal expansion.

This is intentional. Exposed-fastener metal relies on screws through the panel itself. Every screw is a potential leak point and a fixed connection that doesn’t allow movement.

Proper edge metal (hemmed starter at eaves, gable trim at rakes) prevents wind from getting under the panel edge.

If edge details are skipped or done with generic trim, wind can peel the roof during storms.

Details matter more than panel thickness here. A 24-gauge panel with correct clips and edge treatment will outperform a 22-gauge panel with missing edge metal and improper fastening.

Rain Reality: Wind-Driven Water Finds Weak Transitions

Horizontal rain is common in Western Washington during fall and winter storms. Water doesn’t just run down the roof.

It gets pushed sideways into wall transitions, under shingles, around penetrations, and up under poorly flashed edges.

Metal panels handle this well because water moves quickly off the surface. But the transitions are where problems happen.

Step flashing at walls needs to be interwoven with each course of siding, not just tucked behind it.

Wall transitions without proper kickout flashing dump water directly onto siding or into the wall cavity.

Skylights need a pan flashing system, not just caulk. Chimneys need counter-flashing that’s set into the masonry or covered by siding, not surface-mounted.

Underlayment at these intersections is critical. If the metal panel is the primary barrier and underlayment is skipped or low-quality, wind-driven rain will eventually find a way through fastener holes, seams, or gaps.

Metal helps, but only if the flashing and underlayment are done correctly.

Condensation and Ventilation in Metal Roof Assemblies

Condensation under a metal roof happens when warm, moist air from inside the home meets a cold roof deck.

The moisture condenses on the underside of the metal or on the roof deck itself. Over time, this causes rot, mold, and insulation damage.

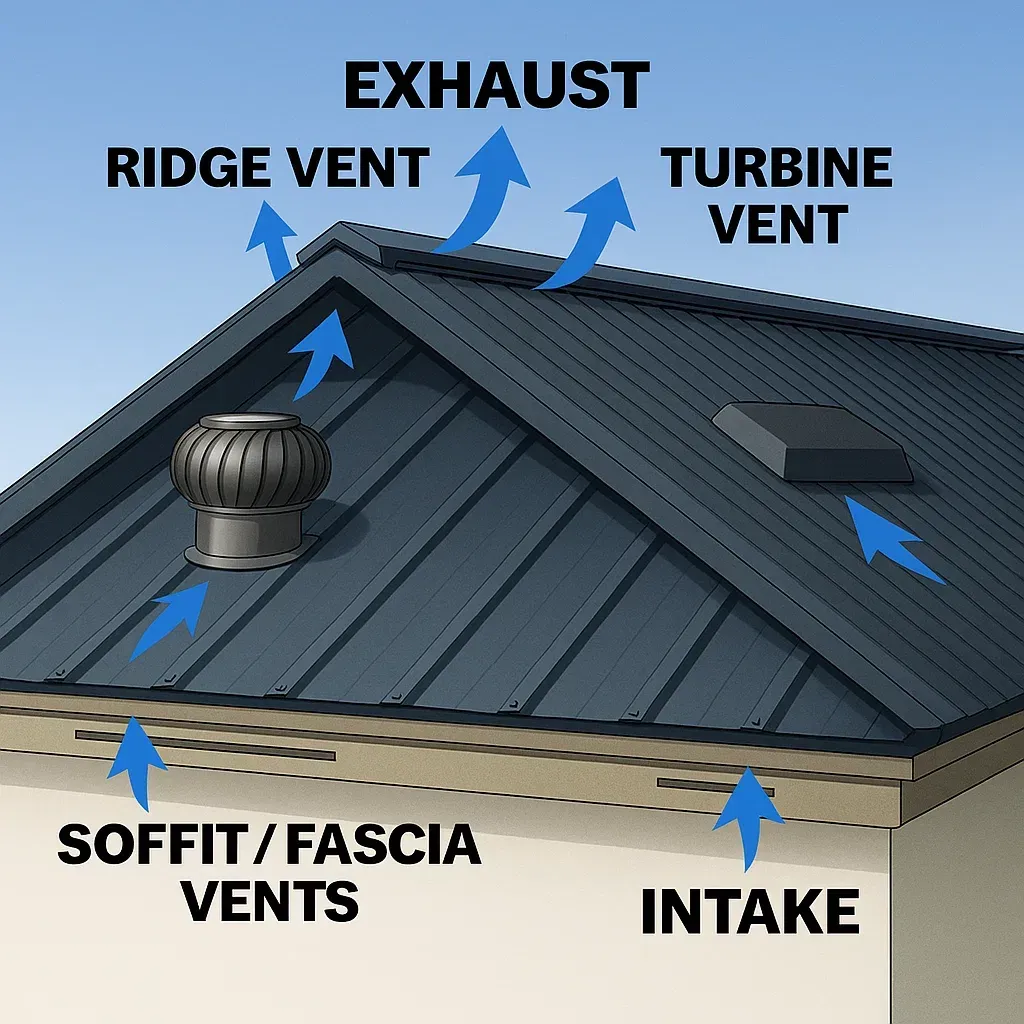

Proper ventilation prevents this. The roof assembly needs balanced intake (soffit vents) and exhaust (ridge vent).

Air moves from soffit to ridge, removing moisture before it condenses.

Underlayment also plays a role. Breathable synthetic underlayment allows some moisture vapor to escape upward while still blocking liquid water.

Non-breathable underlayment or incorrectly installed vapor barriers can trap moisture between layers.

Condensation issues are almost always installation problems, not a flaw with metal roofing itself.

If someone tells you metal roofs “always have condensation problems,” the real issue is improper ventilation or underlayment choice.

Durability and Maintenance in Western Washington

Metal roofs resist moss better than asphalt. Moss needs a rough, porous surface to attach.

Metal is smooth and doesn’t hold moisture the way asphalt granules do. You’ll still see moss on north-facing slopes or shaded areas, but it’s easier to remove and doesn’t degrade the roof surface.

Granule loss isn’t an issue with metal. Asphalt shingles lose granules over time, which exposes the mat underneath and accelerates aging.

Metal doesn’t have that failure mode.

Denting is a tradeoff. Hail, falling branches, and foot traffic can dent metal panels.

This is cosmetic in most cases and doesn’t affect performance, but it’s visible. Thicker gauge panels and certain profiles resist denting better.

Coastal or island homes with salt air should use Kynar or PVDF finishes, which resist corrosion better than polyester or bare Galvalume.

No roof is zero-maintenance. Metal requires less frequent maintenance than asphalt, but fasteners on exposed-fastener roofs should be checked periodically.

Sealants at penetrations eventually dry out and need replacement.

If you’re evaluating profiles and materials, see How to Choose the Right Metal Roof.

Why Installation Quality Matters More Than Panel Brand

Most metal roof failures in the Pacific Northwest come from installation shortcuts, not panel defects.

Common installation issues:

- No movement allowance. Panels are fastened rigidly instead of using clips that allow expansion and contraction. This causes buckling, waves, and fastener pull-through.

- Improper flashing. Step flashing is missing or done incorrectly. Valley metal is the wrong profile. Wall transitions don’t have kickout flashing.

- Low-quality or missing underlayment. Felt paper instead of synthetic. No underlayment at transitions. Wrong product for metal’s heat.

- Ventilation ignored. No soffit intake. Incorrect ridge vent. Imbalanced airflow. Vents blocked by insulation.

- Incorrect fastener type or spacing. Wrong screw length. Over-driven or under-driven fasteners. Missing clips at edges.

You can buy the best panels available and still have a failing roof if the system isn’t installed correctly.

This is why comparing bids based only on price or panel brand misses the point. The scope and installation process matter more.

How to Compare Metal Roofing Bids and Scope

When you’re evaluating proposals for a metal roof, the scope should describe the entire system.

Here’s what should be included:

- Underlayment type and coverage. Should specify synthetic, high-temp rated product. Should cover entire roof deck, not just valleys.

- Panel profile, gauge, and finish. Standing seam vs. exposed-fastener. 24-gauge or 22-gauge. Kynar/PVDF finish for coastal exposure.

- Flashing details. Step flashing at walls, valley metal, chimney cricket and counter-flashing, kickout flashing at wall-to-eave transitions, skylight pan flashing.

- Edge metal and trim. Drip edge at eaves, gable trim at rakes, ridge cap with ventilation provision.

- Fastener/clip system. Concealed clips for standing seam. Spacing and type. Allowance for thermal movement.

- Ventilation plan. Soffit intake, ridge vent, calculation for balanced airflow, how existing vents will be handled.

- Penetration treatment. How pipe boots, vents, exhaust fans will be flashed. Boot type (rubber, metal, or lead).

- Deck repair allowance. What happens if sheathing is damaged during tear-off. How it’s handled in pricing.

- Tear-off and disposal. How many layers are being removed. Disposal method and cost.

- Warranty terms. What’s covered, what’s not, who backs it, and for how long.

Red flags in a bid:

- Price is the only detail provided. No scope breakdown.

- “Flashing included” with no specifics.

- No underlayment type mentioned.

- No ventilation plan or assessment.

- Exposed-fastener metal proposed for a high-wind or coastal site without discussing tradeoffs.

- No mention of how thermal movement is handled.

- Warranty is vague or only covers panels, not labor or installation.

A detailed scope protects you. It shows the contractor understands the system and isn’t planning to shortcut the details.

For related pricing context, see Metal Roof Cost: Standing Seam Pricing.

When Metal Makes Sense (and When Asphalt Is Still a Strong Choice)

Metal roofing makes the most sense if:

- You plan to stay in the home long-term and want to avoid re-roofing.

- Your home is in an exposed location (coastal, island, hilltop, waterfront) with steady wind or salt air.

- Moss is a recurring issue and you want a surface that resists it better.

- You value long-term durability and lower maintenance over upfront cost.

- Your roof has complex transitions, and you want a system that handles them well.

Asphalt shingles are still a strong choice if:

- Budget is a primary constraint and you need a quality roof now.

- You’re planning to sell within 5–10 years and want a cost-effective replacement.

- Your home is in a sheltered location with less wind exposure.

- You prefer a traditional look and don’t want the aesthetic of metal.

There’s no single right answer. It depends on your home, your plans, and what you’re trying to solve.

Frequently Asked Questions

Is metal really worth it in the PNW, or is it overkill?

Metal performs well here because of how it sheds water, resists moss, and handles wind when installed correctly.

Whether it’s worth the cost depends on how long you plan to own the home and whether you want to avoid re-roofing.

It’s not overkill if you value long-term durability, but asphalt is still a valid option for shorter timelines or budget constraints.

Will a metal roof be loud in the rain?

Not if it’s installed over solid sheathing with underlayment. The deck and underlayment absorb sound.

You might hear light tapping during heavy rain if you’re in an attic space, but it’s not loud inside finished living areas.

Homes with vaulted ceilings and no attic buffer may hear more, but it’s not the drumming sound most people imagine.

What about condensation under metal?

Condensation happens when warm, moist air meets a cold surface.

Proper ventilation (balanced intake and exhaust) and the right underlayment prevent it.

If a metal roof has condensation issues, it’s almost always a ventilation or installation problem, not a flaw with metal itself.

Does coastal air or salt cause rust?

Galvalume panels with a quality finish (Kynar or PVDF) resist corrosion well in coastal environments.

Bare steel or low-grade finishes will corrode over time near salt water.

If you’re on an island or near the coast, specify a corrosion-resistant finish and avoid cut edges that expose raw metal.

Is standing seam necessary, or is exposed-fastener fine?

Standing seam is better for wind resistance, longevity, and weather-tightness because fasteners are concealed and the panels can move with thermal expansion.

Exposed-fastener panels are less expensive and work fine in lower-wind areas, but every screw is a potential leak point and the roof is harder to maintain long-term.

For coastal or high-wind sites, standing seam is worth it.

Does metal increase resale value or just cost more?

Metal roofing can increase resale value if the buyer values durability and low maintenance.

It’s a selling point in markets where buyers expect long-term performance.

But not every buyer will pay more for it, and you likely won’t recover the full cost difference between metal and asphalt at resale.

The value is more about avoiding future re-roofing than immediate return on investment.

How do I know if my roof pitch is too low for metal?

Standing seam metal can be installed on pitches as low as 2:12 with the right underlayment and details.

Exposed-fastener panels typically need 3:12 or steeper.

If your roof is low-slope or flat, discuss pitch requirements and waterproofing details with your contractor.

Some profiles handle low slopes better than others.

Can I install metal over existing shingles?

It’s possible, but not always recommended.

Installing over shingles skips the opportunity to inspect and repair the deck, can create ventilation issues, and adds weight.

Most manufacturers and contractors prefer a full tear-off to ensure proper underlayment, flashing, and deck condition.

If budget is tight, ask about the tradeoffs and whether your specific roof is a good candidate.

What to Do Next

If you’re considering metal roofing for your home in Western Washington, start with an inspection.

A proper evaluation looks at roof pitch, ventilation, existing deck condition, flashing requirements, and exposure factors like wind and salt air.

You should walk away with a clear scope that explains the system, not just the panels.

What underlayment will be used, how transitions will be flashed, how ventilation will be balanced, and how the roof will handle movement and wind uplift.

Wind Proof Roofing works with homeowners throughout the Puget Sound and coastal areas who want a roof built to handle PNW weather.

We can inspect your roof, evaluate the details, and give you a transparent scope for a metal roofing system that fits your home and your plans.

No pressure. Just clarity on what the roof needs and what your options are.