Part 2: Gauge, Paint Finish, Panel Profiles & Life Expectancy

If you read Part 1, you already understand why metal roofing outperforms most traditional systems and why standing seam is often the best residential option.

In Part 2, we go deeper into the details that actually determine performance, longevity, and cost — the things that are often glossed over online but make a massive difference in the real world.

Choosing a metal roof isn’t just about looks.

The gauge of the steel, the paint system, the panel profile, and how everything works together will decide how long your roof lasts — especially in the Pacific Northwest, where moisture, wind, and temperature swings are constant realities.

Metal Gauge Explained: Thickness Matters More Than You Think

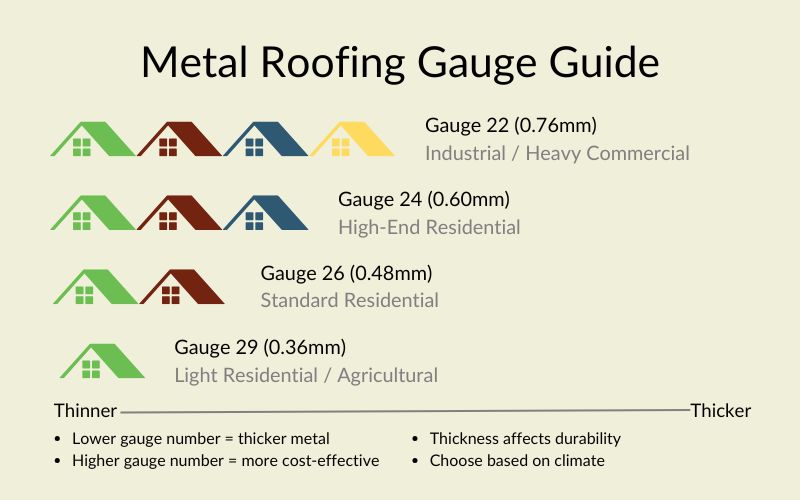

Gauge refers to the thickness of the metal.

The lower the gauge number, the thicker — and stronger — the steel.

Common Residential Metal Roof Gauges

- 29 gauge – Entry-level

More flexible, easier to oil-can, shorter lifespan - 26 gauge – Solid mid-range

Good balance of cost, strength, and durability - 24 gauge – Premium residential

Stiffer panels, flatter appearance, longest life

Why Gauge Matters

Thicker steel:

- Resists denting from debris and foot traffic

- Handles wind uplift better

- Manages thermal movement more predictably

- Holds clips, fasteners, and seams tighter over decades

In high-wind and coastal environments like the Pacific Northwest, 24- or 26-gauge standing seam is usually the smart long-term choice.

A thinner panel may save money upfront — but it often costs more over time in repairs, appearance issues, and earlier replacement.

Paint Finish: The Difference Between a 20-Year Roof and a 50-Year Roof

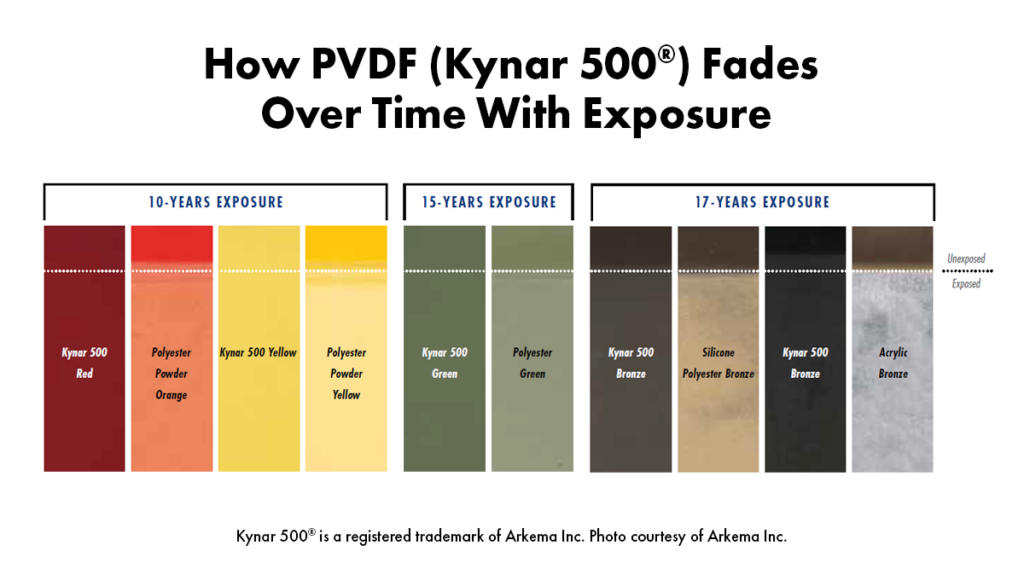

Not all metal roofs fade the same.

The paint system is just as important as the steel underneath it.

The Gold Standard: Kynar 500 / PVDF

- Exceptional UV resistance

- Superior color retention

- Real-world lifespan of 40–50+ years

- Minimal chalking and fading over time

Lower-Cost Paint Systems

- SMP or polyester coatings

- Fade and chalk faster

- Shorter warranties

- Greater risk of uneven color over time

If long-term appearance and resale value matter, Kynar-based finishes are non-negotiable — especially in climates with constant moisture, cloud cover, and intermittent sun exposure like the PNW.

Panel Profiles: It’s Not Just Standing Seam vs Corrugated

Panel profile affects water shedding, wind resistance, expansion movement, and aesthetics.

Standing Seam Panels

- Concealed fasteners

- Vertical seams keep water out

- Clean, architectural appearance

- Best option for most residential homes

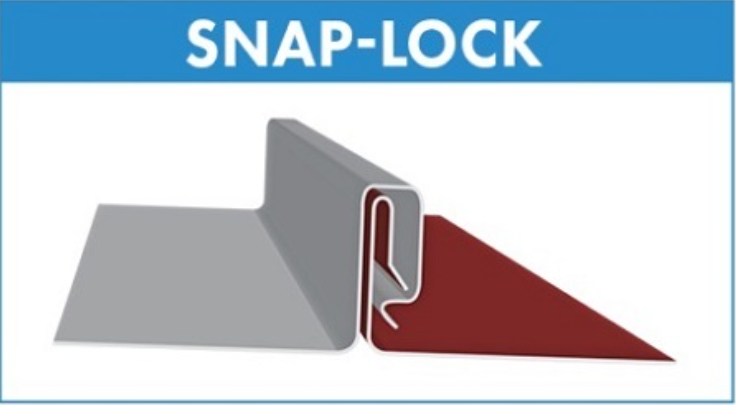

Snap-Lock Standing Seam

- Ideal for pitches 3:12 and above

- Faster installation

- Excellent performance when properly detailed

Mechanical Seam Standing Seam

- Seams are mechanically folded

- Required for low-slope roofs

- Maximum weather resistance

- More labor-intensive — but extremely durable

Exposed-Fastener Panels

- Screws penetrate the panel surface

- Lower upfront cost

- Washers and fasteners are wear points

- Typically shorter lifespan

For most homes, standing seam with concealed clips offers the best balance of performance, longevity, and curb appeal.

Life Expectancy: What You Can Actually Expect From a Metal Roof

When properly designed and installed, a metal roof isn’t a short-term solution — it’s often the last roof you’ll ever need.

Realistic Lifespan Expectations

- Entry-level metal: 25–30 years

- 26-gauge with Kynar: 40+ years

- 24-gauge standing seam: 50+ years

What shortens lifespan is rarely the panel itself.

It’s almost always

- Poor flashing details

- Incorrect clip or fastener spacing

- Inadequate underlayment

- Corners cut at valleys, walls, and penetrations

A metal roof is a system, not just panels.

Why Details Matter More Than Price Per Square

Homeowners often ask for pricing before understanding the variables.

The truth is, small design choices drastically change cost and performance.

Things that affect both price and lifespan:

- Panel width and rib height

- Gauge selection

- Paint system

- Valley design

- Chimney and wall flashing complexity

- Underlayment type

- Roof pitch and geometry

This is why responsible contractors avoid blanket pricing.

Every roof is different — and every detail matters.

Final Thoughts: Choosing the Right Metal Roof

A metal roof done right is quieter, stronger, more energy-efficient, and dramatically longer-lasting than most alternatives — but only if the materials, design, and installation are aligned.

If you’re considering metal, focus less on the cheapest quote and more on:

- Gauge

- Paint system

- Panel profile

- Proven installation experience

Those are the factors that separate a roof that simply looks good from one that performs flawlessly for decades.