A Homeowner’s Guide to Standing Seam Metal Roof Pricing

One of the most common questions homeowners ask is:

“How much does a standing seam metal roof cost?”

The honest answer is: it depends—not in a vague or evasive way, but because metal roofing pricing is directly tied to design, materials, and installation details that vary from home to home.

Standing seam metal roofing is a premium roofing system. Unlike asphalt shingles, it isn’t a commodity product. It’s an engineered system, and small variables can have a big impact on the final cost.

Below is a clear, homeowner-friendly breakdown of what actually drives the price of a metal roof—and why estimates can vary so much.

Why Standing Seam Metal Roofing Varies in Price

No two metal roofs are truly the same. Even homes with similar square footage can differ by thousands of dollars once real-world details are factored in.

Roof Complexity

Roof design plays a major role in cost. Key factors include:

- Number of roof planes

- Valleys and transitions

- Dormers and architectural features

- Roof pitch (steepness)

- Access and safety requirements

A simple gable roof will always cost less than a complex roof with multiple valleys, facets, and elevations. Complexity increases labor time, fabrication, and flashing work.

Metal Panel Type & Gauge

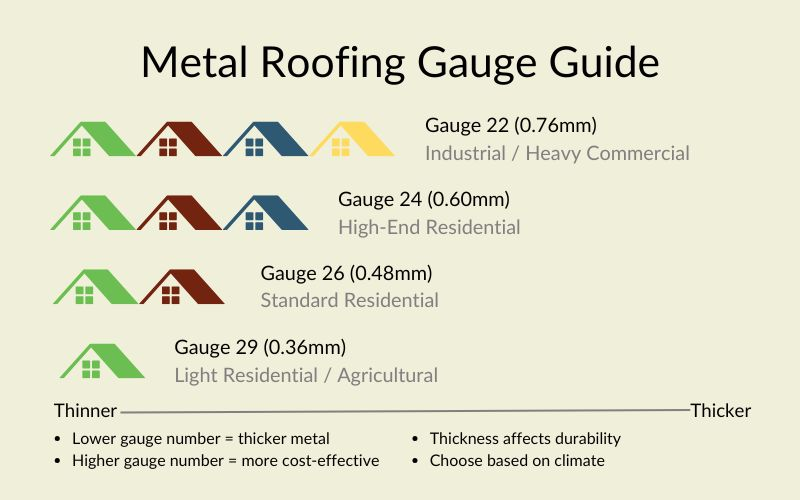

Standing seam panels are available in different thicknesses (gauges), most commonly:

- 24-gauge — thicker, heavier, premium

- 26-gauge — slightly lighter and more economical

Thicker metal:

- Resists denting better

- Handles wind loads more effectively

- Costs more in both material and handling

Gauge choice alone can noticeably change pricing—and performance.

Paint Finish & Coating System

The paint system is one of the most important (and most overlooked) parts of a metal roof.

Higher-end finishes:

- Resist fading and chalking

- Perform better in high-moisture and coastal environments

- Carry longer manufacturer warranties

These coatings cost more upfront, but they play a major role in how the roof looks and performs 20–40 years down the road.

Valleys, Flashing & Custom Metal Work

This is where quality truly shows—and where many bids differ.

Standing seam metal roofs require:

- Custom valley metal

- Precision flashing at walls, chimneys, skylights, and penetrations

- Clean transitions at ridges, eaves, and rakes

Every valley and flashing detail adds labor, material, and fabrication time. These components are not optional—they are critical to water management and long-term performance.

Underlayment & Waterproofing

The metal panels are only the outer shell. What’s underneath matters just as much.

High-quality metal roof systems often include:

- High-temperature synthetic underlayment

- Ice & water shield at eaves, valleys, and penetrations

- Proper separation layers to protect the metal and roof decking

Cutting corners here can shorten the life of the roof—even if the panels themselves could last decades.

Labor, Layout & Precision Installation

Metal roofing is not installed like shingles.

Proper installation requires:

- Precise layout and panel alignment

- Allowances for thermal expansion and contraction

- Specialized tools and trained installers

This work is more technical and time-intensive, which is reflected in the price.

Why “Per Square” Pricing Is Often Misleading

You’ll often see metal roof pricing advertised as a flat number “per square” (a square = 100 sq ft).

In practice, that approach rarely tells the full story.

Two roofs with the same square footage can differ significantly in cost once you account for:

- Valleys and flashing complexity

- Roof pitch

- Metal gauge and finish

- Underlayment requirements

- Access and safety considerations

Accurate pricing requires measuring and accounting for every detail—down to the last flashing piece and fastener. That level of precision protects both the homeowner and the performance of the roof.

Is It Normal for a Metal Roof to Cost More Than Asphalt?

Yes—and for good reason.

Standing seam metal roofing typically costs more upfront than asphalt shingles because it offers:

- 40–70+ year service life

- Superior water and wind resistance

- Minimal maintenance

- Clean, architectural aesthetics

- Long-term value instead of short-term replacement

Asphalt shingles are still a solid, affordable roofing option—but they’re designed for a different lifespan and performance level.

Metal Roofing in the Pacific Northwest: Cost vs. Value

In a region known for:

- Persistent rainfall

- Moisture retention

- Wind exposure

- Moss growth

Standing seam metal roofing performs exceptionally well.

While the initial cost may be higher, many homeowners find that the durability, reduced maintenance, and longevity outweigh the upfront investment—especially compared to replacing asphalt roofs multiple times over the same period.

Final Thoughts on Metal Roof Pricing

Standing seam metal roofing is not a commodity. It’s a custom-built roofing system.

The cost reflects:

- Engineering

- Materials

- Craftsmanship

- Long-term performance

If you’re exploring metal roofing, the most important step isn’t chasing the lowest number—it’s understanding what’s included, how it’s installed, and why the details matter.

A properly designed and professionally installed metal roof should protect your home for decades—and that’s where the real value lies.